Time:2024-08-30

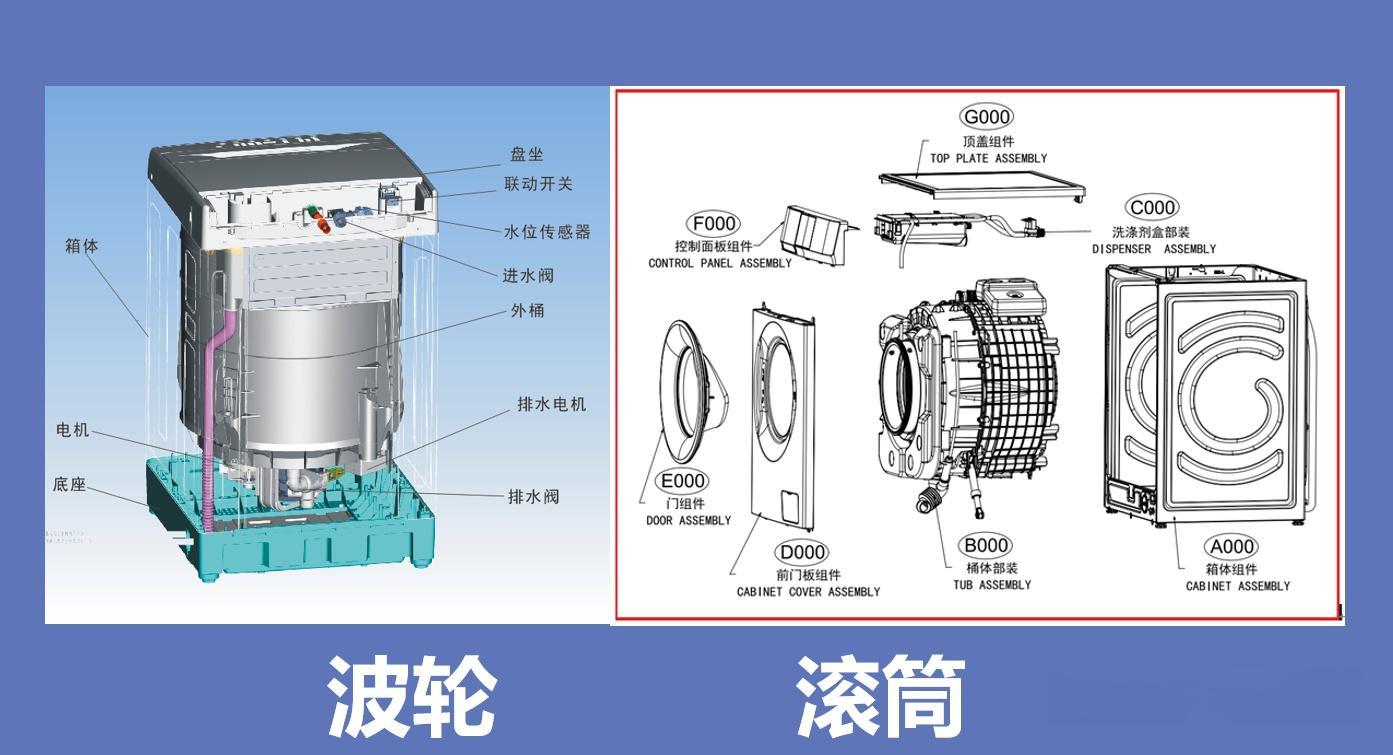

The structure of a drum washing machine mainly consists of the following parts:

Box:

The box is the external frame of a drum washing machine, usually welded from side panels, top panels, bottom panels, and front and rear panels, providing support and protection for various internal components of the washing machine.

The box is usually equipped with external interfaces such as control panels, inlet pipes, and drainage pipes.

control panel:

The control panel is the interface for users to interact with the washing machine, used to set washing programs, select washing modes, adjust washing time and temperature, etc.

It is usually composed of electronic components, display screens, buttons, etc., fixed on the top or side of the box.

Washing and dehydration components:

The washing and dehydration component is the core component of a drum washing machine, including the drum, motor, belt, bearings, etc.

The drum is usually made of stainless steel and has protrusions inside to enhance the washing effect; The motor drives the drum to rotate through a belt, achieving washing and dehydration functions.

Inlet/outlet system:

The water inlet system includes components such as inlet pipes and inlet valves, which are used to inject washing water into the washing machine.

The drainage system includes components such as drainage pumps and drainage pipes, which are used to discharge the wastewater after washing out of the washing machine.

Door components:

The door component is the inlet and outlet for clothing, usually composed of door glass, door handles, door locks, and other components.

The door component also has a sealing function to prevent water from splashing out during the washing process.

Electrical control system:

The electrical control system is the "brain" of the drum washing machine, responsible for controlling the entire working process of the washing machine.

It is usually composed of components such as program controllers, motor drivers, sensors, etc., and precise control of each component is achieved through circuit connections.

Recommended glue for washing machines:

sealant:

Purpose: Mainly used for sealing parts such as washing machine doors, water inlet pipes, and drainage pipes to prevent water leakage.

Features: Water resistance, aging resistance, chemical medium corrosion resistance, good adhesion and sealing properties.

Recommended products:

Visiochem reactive polyurethane hot melt adhesive: suitable for bonding and edge sealing of plastics, metals, ceramics and other materials, especially for fixing and sealing the edges of washing machine bucket covers and other parts.

Visiochem water-based polyurethane sealant: This is a reactive sealant suitable for sealing the top covers of equipment such as washing machines, dryers, refrigerators, and freezers. It has excellent weather resistance and sealing performance.

Fixed adhesive:

Purpose: Used for fixing internal components of washing machines, such as electronic components and transmission parts on control panels.

Features: High strength, high adhesion, able to maintain stable bonding effect in various environments.

Recommended products:

Visiochem bearing retaining adhesive: Especially suitable for fixing the steel shaft of washing machine motors, it has excellent oil and chemical resistance properties.

Visiochem quick drying adhesive: suitable for instant strong bonding of plastic parts such as PP drainage pipes in washing machines, with fast drying and firm bonding.

Shock absorber adhesive:

Purpose: Used to reduce vibration and noise during the operation of washing machines, usually used for filling or bonding parts such as motor bases and shock absorbers.

Characteristics: It has good elasticity and shock absorption effect, and can absorb and disperse vibration energy.

Recommended products:

Visiochem polyurethane sealant: This type of sealant not only has good adhesion and chemical stability, but also has high elasticity, making it suitable for sealing shock absorber components inside washing machines.